Special wire ropes & High Performance Wire Ropes by verope

verope develops and supplies high-performance special wire ropes – designed for maximum strength, safety, and reliability.

Our ropes are used wherever heavy loads must be lifted, moved, or held securely: in cranes, ports, offshore platforms, mining, and many other industries.

This page explains everything about wire rope construction, components, performance, and the technology behind verope’s products.

What are Special wire ropes?

Special wire ropes (Spezialdrahtseile or high performance ropes) are steel wire ropes that go beyond standard lifting ropes. They are engineered for high fatigue resistance, long service life, and exceptional strength under extreme conditions. verope specializes in these high-performance ropes, combining advanced engineering, materials, and processing know-how.

Alternative terms:

special wire rope, Spezialdrahtseil, high performance rope, steel wire rope, non-rotation rope, rotation-resistant rope.

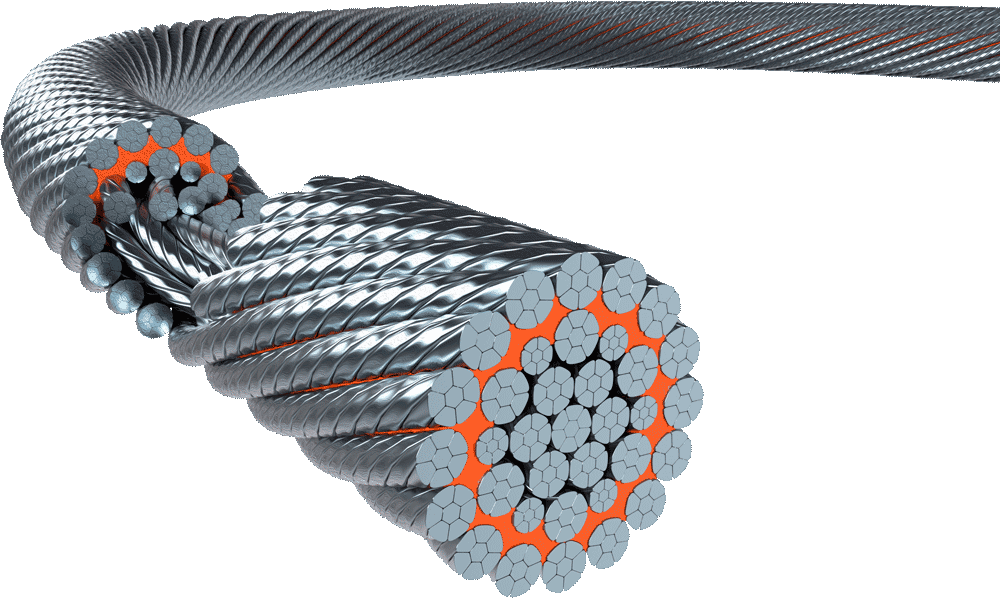

Rope Construction – The Anatomy of a High Performance Rope

Wire and Strand Materials

High-tensile steel wires are arranged in strands. Compacting and surface treatment improve fatigue and abrasion resistance. Compacted strands reduce rope diameter and provide smoother spooling on drums.

Rope Core

Depending on the application, verope uses different rope cores:

- Steel core (IWRC): very strong and crush-resistant

- Fibre core (FC): flexible and lightweight

- Plastic layer: protects the core and prevents inner corrosion

Number of Strands

Typical high-performance ropes are 4-, 8-, 9-, or 10-strand constructions.

For example: verotop S, veropro 8, verotech 10 – all optimized for specific use cases.

Lay Direction and Rope Type

Lang’s lay, regular lay, rotation-resistant or non-rotation-resistant – verope offers the full spectrum. Rotation-resistant ropes are essential for tower cranes, offshore cranes, and deck cranes. Non-rotation-resistant ropes provide high stability for general lifting applications.

Compaction and Surface Treatment

Many verope ropes are compacted and sometimes hammered to optimize breaking strength and improve service life. This also enhances spooling behaviour in multi-layer winches.

Performance Features and Benefits

The factors outlined above ensure that verope special wire ropes deliver measurable advantages, including extremely high breaking strength and safety factors, excellent fatigue life thanks to compacted strand technology, superior abrasion and crush resistance, and optimized spooling behaviour on multi-layer drums. In addition, they offer a longer service life with reduced downtime, reliable corrosion protection through plastic layers or galvanizing, and excellent handling and installation characteristics.

verope Product Range

Rotation-resistant ropes

Non-rotation-resistant ropes

Resources

Markets and Applications

Industries We Serve

verope offers specialized wire ropes and dependable services tailored to a wide spectrum of industries. Our products are engineered to deliver safety, durability, and long-term performance, even under extreme operating conditions. An overview of all markets and applications can be found here: Industries overview

Offshore Industry

For offshore cranes, winches, and subsea operations, verope wire ropes provide high fatigue strength and excellent corrosion resistance. Designed for harsh marine environments, they meet the highest performance and safety standards required for offshore lifting and handling. Learn more about Offshore solutions

Port Industry

In ports and terminals worldwide, verope ropes are used for container handling, ship-to-shore cranes, and bulk material loaders. They are engineered for continuous high-cycle operation, reliable spooling behaviour, and reduced downtime in demanding logistics environments. Port & terminal applications

Heavy Industry

From overhead cranes to steel mills and heavy manufacturing, verope wire ropes deliver exceptional strength and fatigue life. They are built to withstand tough working conditions, high loads, and repetitive lifting cycles common in industrial production. Heavy industry solutions

Construction Industry

Tower cranes, crawler cranes, and hoists rely on flexible and durable ropes capable of handling dynamic loads and multi-layer spooling. verope ropes are engineered to support efficient operation on construction sites while maintaining high safety margins. Construction industry solutions

Shipping and Deck Cranes

For shipboard lifting and cargo handling, verope supplies robust wire ropes with excellent corrosion resistance and dimensional stability. These ropes are designed to perform reliably in maritime environments and under changing load conditions. Shipping industry solutions

Mining

Mining companies worldwide trust verope ropes for hoisting, dragline, and material handling applications. High safety margins, long service life, and consistent performance make them suitable for harsh environments and continuous operation. Mining industry solutions

Renewable Energies

In offshore wind and other renewable energy projects, performance and safety are critical. verope wire ropes support installation, maintenance, and lifting operations where reliability and precision are essential. Renewable energy solutions

Elevator Market – RiseTec by verope

In addition to the industries above, we also serve the elevator wire rope market with RiseTec by verope. RiseTec ropes are specifically designed for elevator applications, combining long service life, smooth running characteristics, and consistent quality.

RiseTec benefits from verope’s global infrastructure and service network, enabling fast response times and local support worldwide. We are proud to already support one of the leading OEMs in the elevator industry, underscoring our commitment to quality, reliability, and partnership.

We believe great service goes beyond meeting expectations. Whether you are a small business or a global OEM, we aim to be a dependable partner focused on the right solution for your application. Discover RiseTec elevator wire ropes

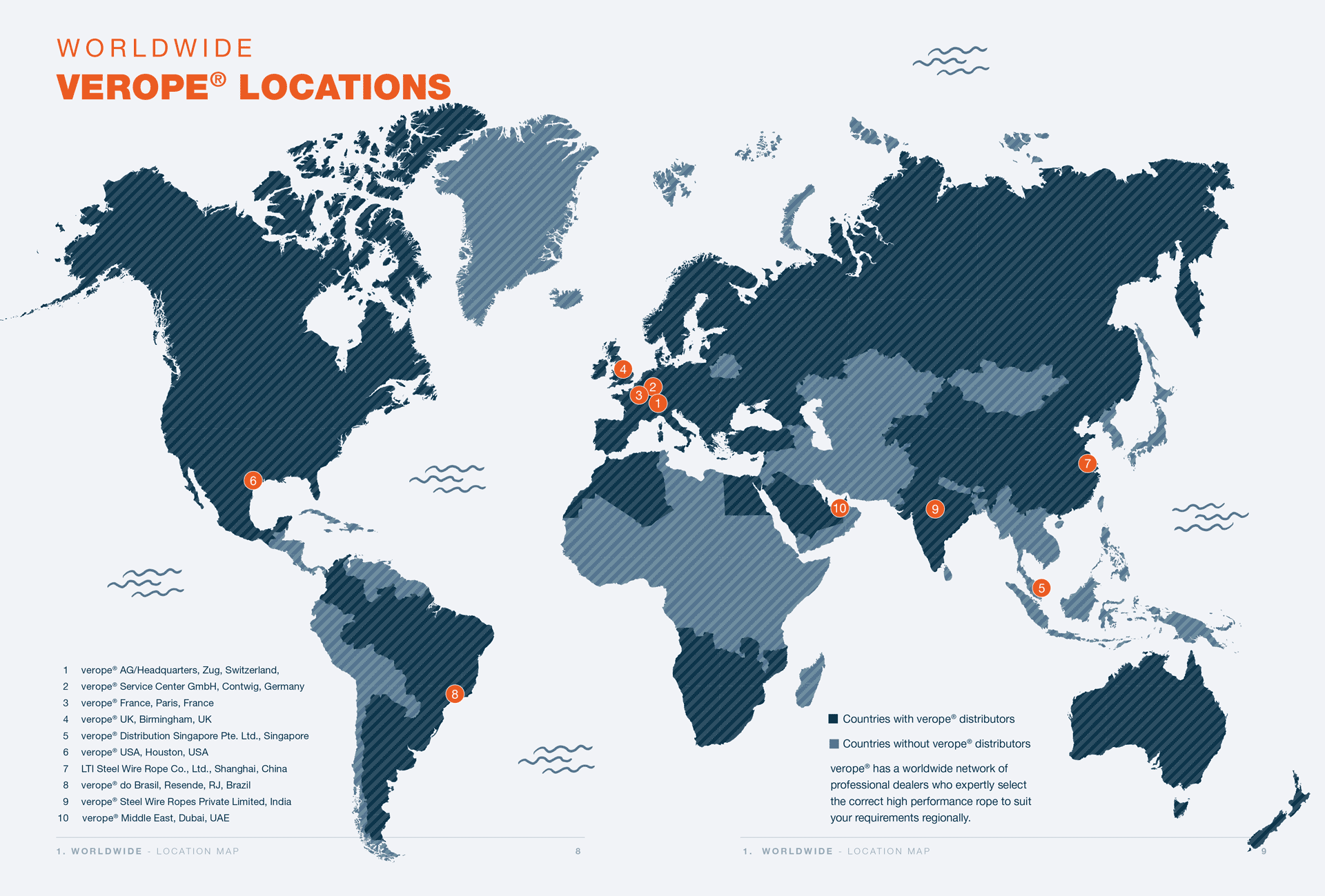

verope locations worldwide

Partners and Related Brands

- Kiswire – production partner and joint venture manufacturer

- KV R&D – research and development partnership

- VSC Service Center Contwig – rope service and logistics hub

- verope Mining Ropes – dedicated rope range for mining operations

- RiseTec Elevator Ropes by verope – high-performance ropes for elevator applications

Get in Touch

Looking for the right high performance rope for your project?

Contact verope for consultation, technical support, or distributor contacts.

General contact: verope.com/contact