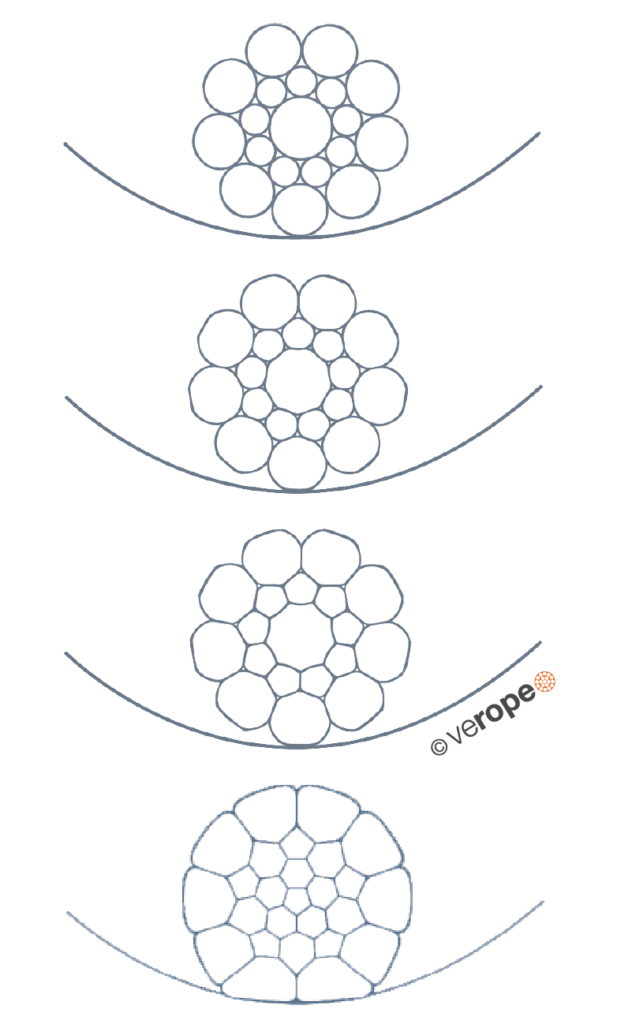

Changes in line pull will cause changes in the rope length. Rope sections lying on a sheave or on the first wraps of a drum can only adapt to the changing line pull by sliding over the groove surface of the sheave or the drum when the length change occurs. This relative motion will cause abrasion (both in the grooves and on the special wire rope). Using less and therefore larger outer wires can increase the wear resistance of the rope.

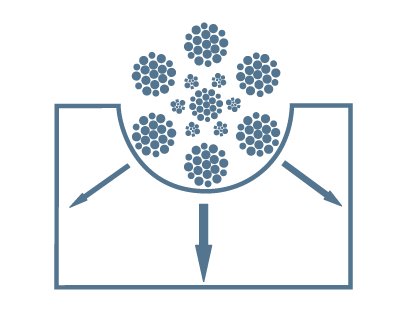

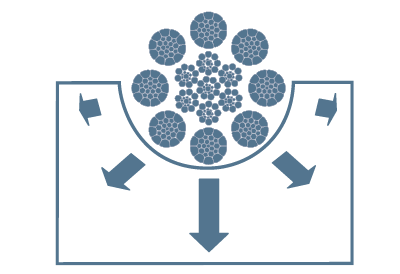

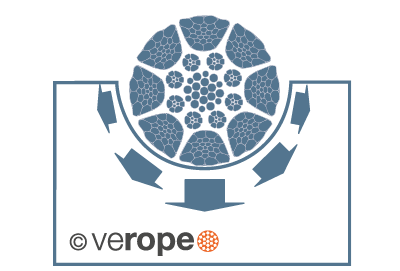

The pressure between the sheave and the rope can be minimized due to optimized contact areas; therefore also the wear of the rope can be minimized (figure 24). The wear resistance can also be influenced by the metallurgy of the outer strands.

Unique special wire ropes

- High quality wire rod

- State of the art design

- Experienced production & innovative rope tests

- Careful development due computerized wire rope sizing

- Manufactured by the world’s largest wire product manufacturers using the latest machinery

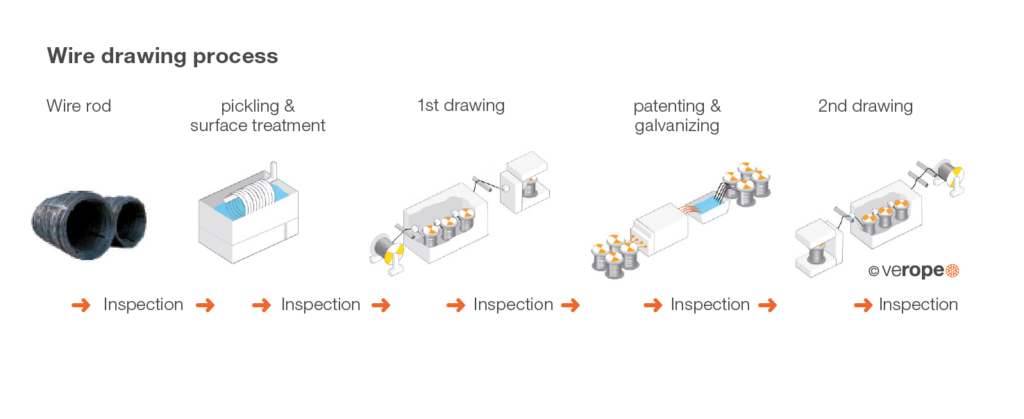

- Due to Kiswire’s own wire drawing the raw material is of unsurpassed quality

- Unique design