verope Special Wire Ropes are designed to achieve high breaking loads and better strength to weight ratios. High ductility wires drawn to controlled tolerances are stranded and closed into a rope constructed with optimized gap spacing between the individual rope elements. verope products achieve an increased fill factor by using compacted strands as well as rotary swaging in their method of rope construction. Parallel lay elements in the rope composition increase the metallic cross sectional area. Crane designers use the technical advantages provided by the rope manufacturers to reduce the drum and sheave dimensions in line with maintaining the recommended D/d ratios. The material cost and weight saving effect on the static design of the crane elements is substantial.

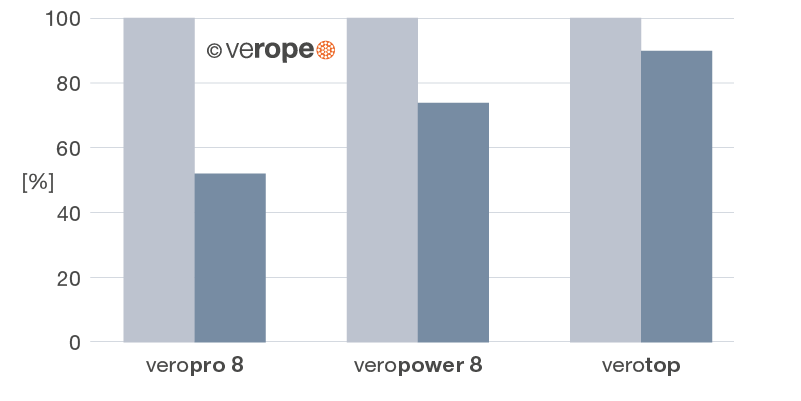

Figure 30: Breaking strengths of non-rotation resistant ropes

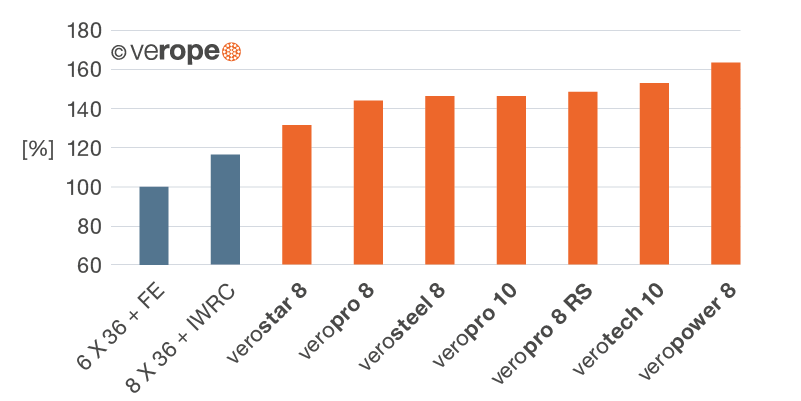

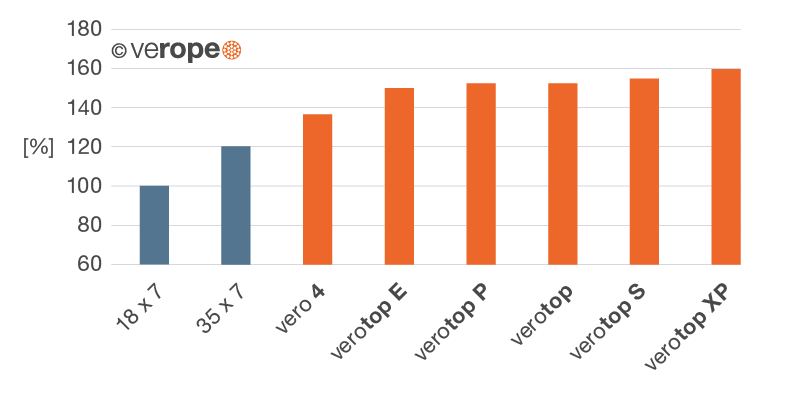

Figure 31: Breaking strengths of rotation-resistant ropes

Breaking strengths and Swivel

The minimum breaking strength given in catalogues is valid for wire ropes whose ends are protected against twisting. The breaking strengths of nonrotation resistant ropes are reduced significantly by the usage of a swivel. Even if the rope would not immediately break under the nominal load, several now overloaded elements of the rope will become disproportionally loaded. Also structural changes, like basket deformation could appear very fast. Therefore, non-rotation resistant ropes should not be used with a swivel.