Standard ropes often do not meet the high requirements of many applications of wire ropes. Higher demands for rope lifetime, breaking strengths, rotational stability, flexibility, structural stability and spooling behavior can only be fulfilled by special wire ropes. It is for these reasons that many engineers and end users resort to verope® special wire ropes.

Plastic Layer

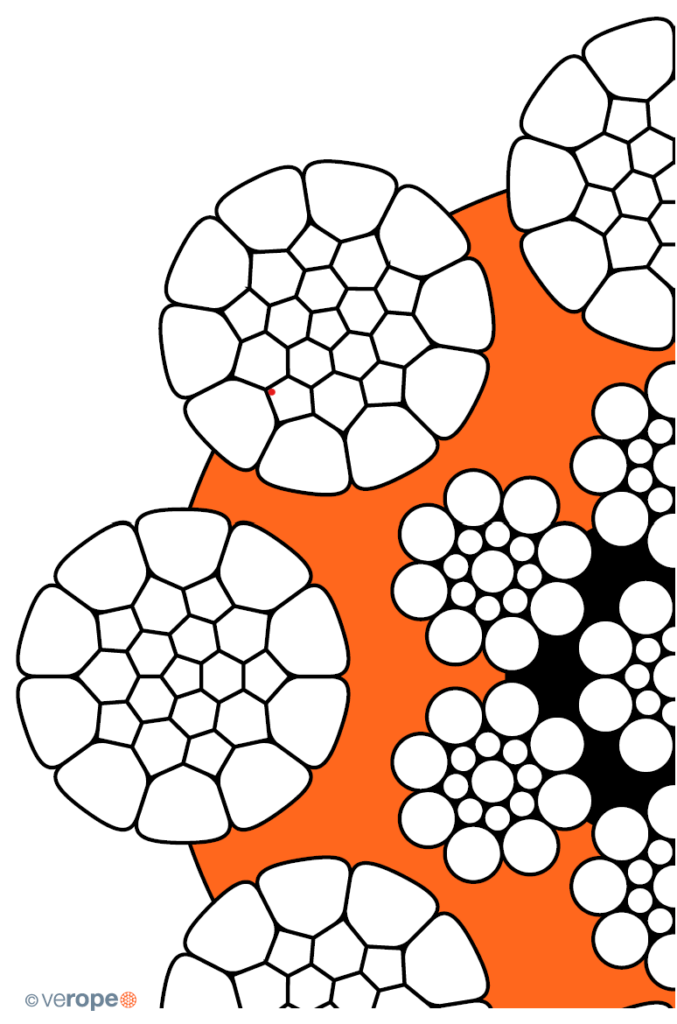

Many verope products have a plastic layer between the steel core and the outer strands. This intermediate layer stabilizes the form stability of the rope like a flexible corset and increases the lifetime of a rope especially under difficult working conditions. The intermediate plastic layer avoids the infiltration of water and dirt, which helps avoiding corrosion in the steel core. This cushion avoids internal steel-to-steel cross over contacts and limits as such the damage caused by this phenomenon (figure 29).

The main advantages are:

• Prevents internal wire breaks

• Seals in rope lubricant

• Keeps out infiltration of water, dust, etc…

• Reduces the internal stress

• Improves the form stability of the rope

• Absorbs dynamical energy

• Reduces the noise level