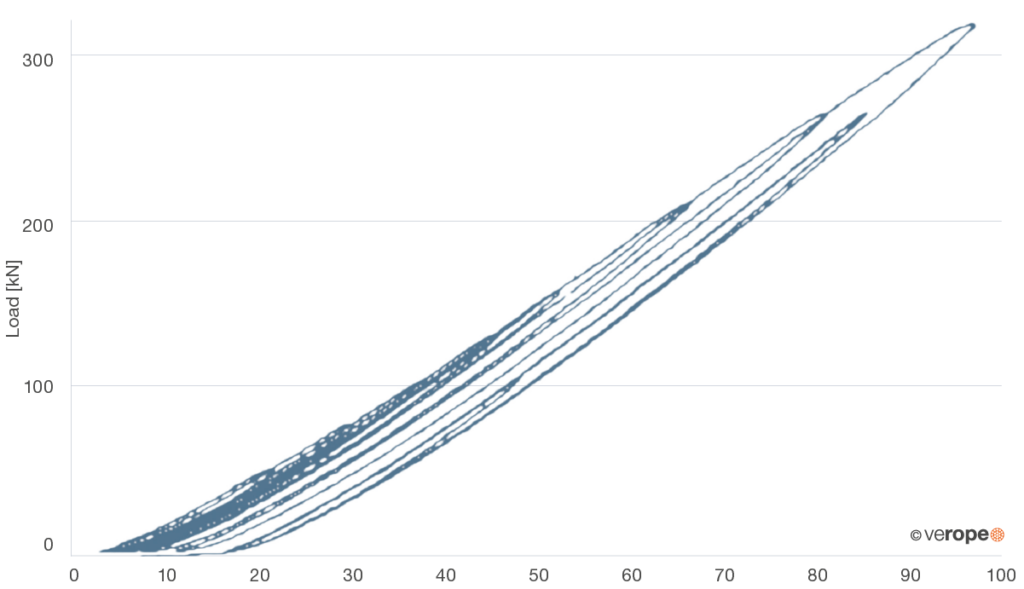

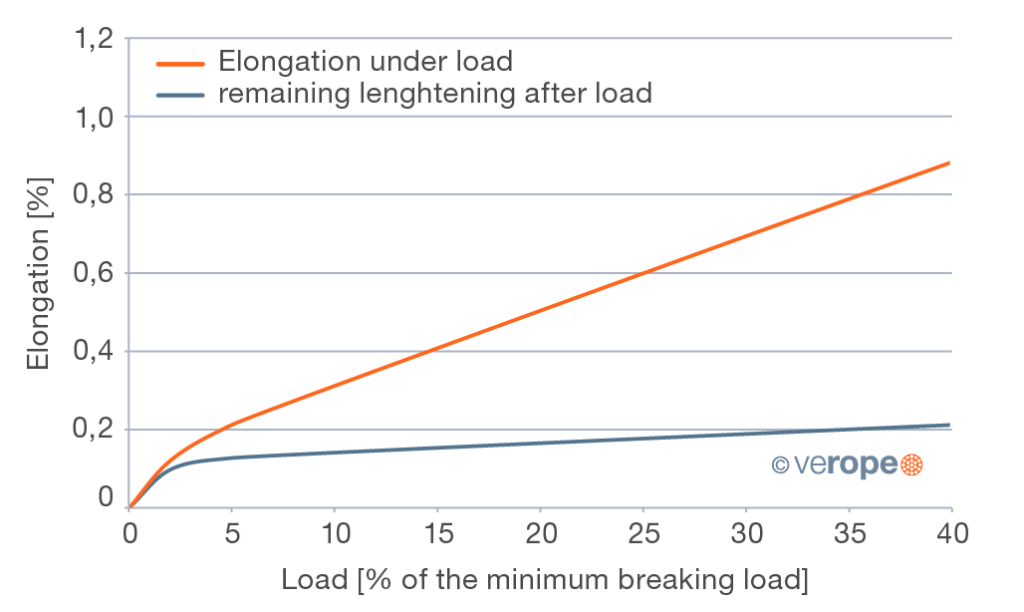

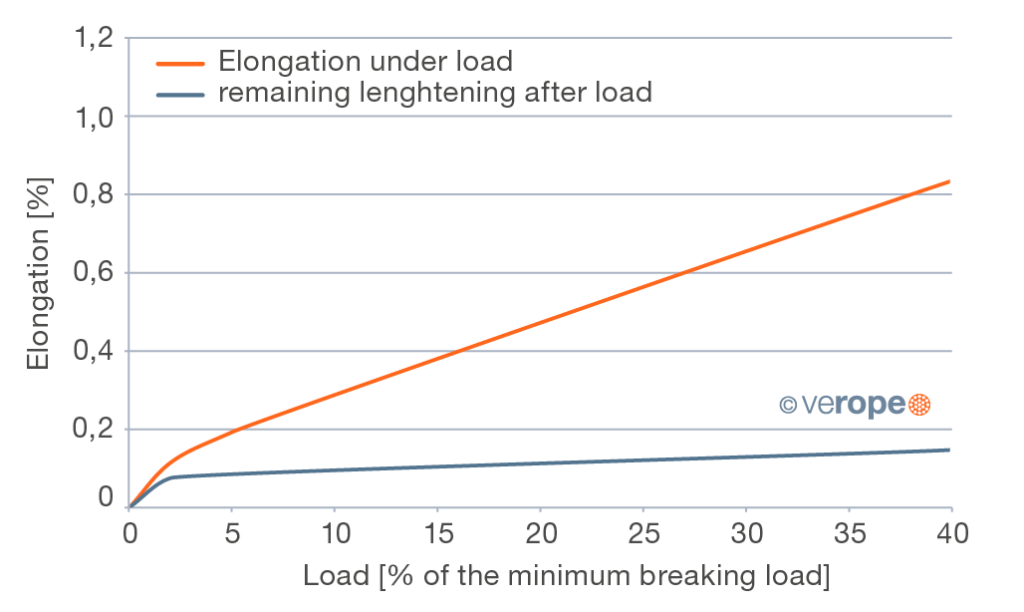

In many applications the exact knowledge of the deformation behavior of wire ropes is of great importance. verope® has investigated in many work-intensive tests the modulus of elasticity (lengthwise and transverse), the elastic and plastic deformation as well as the diameter reduction of its products. Many technical parameters of the rope can be determined by the creation of a load-elongation diagram (figure 54). verope® loads and relieves the ropes in steps and determines the elongation under load as well as the remaining elongation after discharge. The modulus of elasticity is determined from the gradient of the linear area of the load curves. At the same time the diameter reduction in dependence of the load is measured. In order to be able to determine also the breaking strength and the elongation at break, the ropes are loaded up to break.

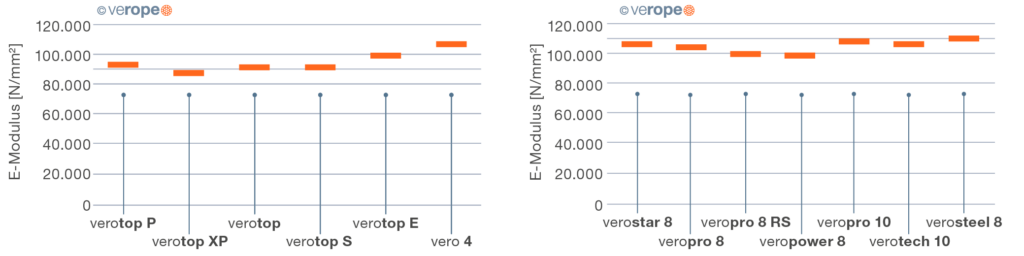

Modulus of elasticity

Within a rope construction, the modulus of elasticity varies slightly in dependence of the rope diameter, the lay type (lang’s lay or regular lay) and of the tensile strength of the wire (figure 55). As a rule, the modulus of elasticity of wire ropes increases over the lifetime of the rope.

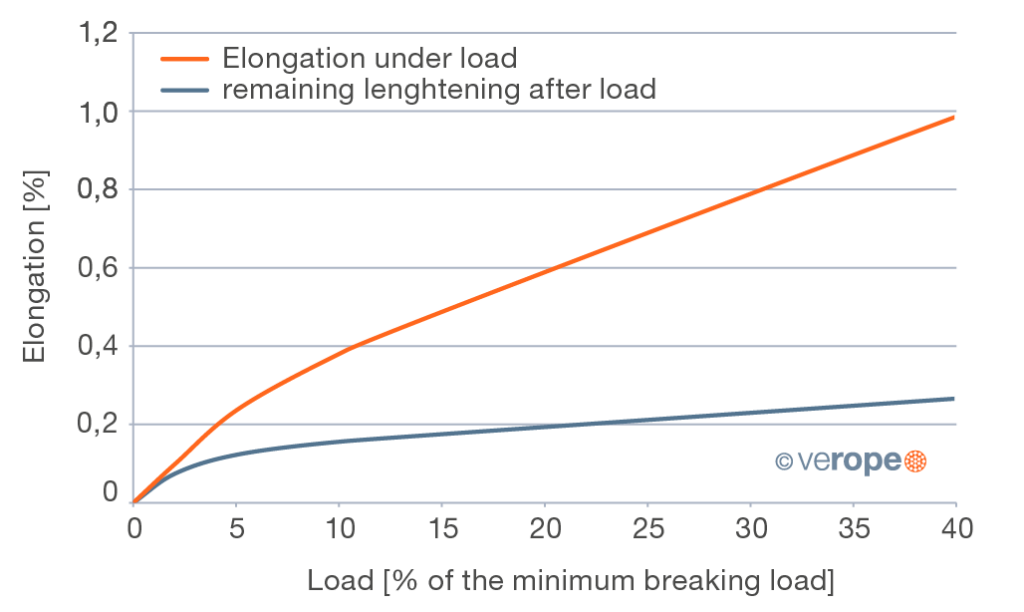

Elongation

In particular with suspension ropes, but also with running ropes an exact knowledge of the elongation of the rope under load and the remaining rope lengthening after load is important. verope® has measured these relevant values for all its products with high precision on long test lengths. Below you can find measured values of typical verope® rope constructions. We are pleased to provide you with the results of other verope® rope construction for your interpretation.

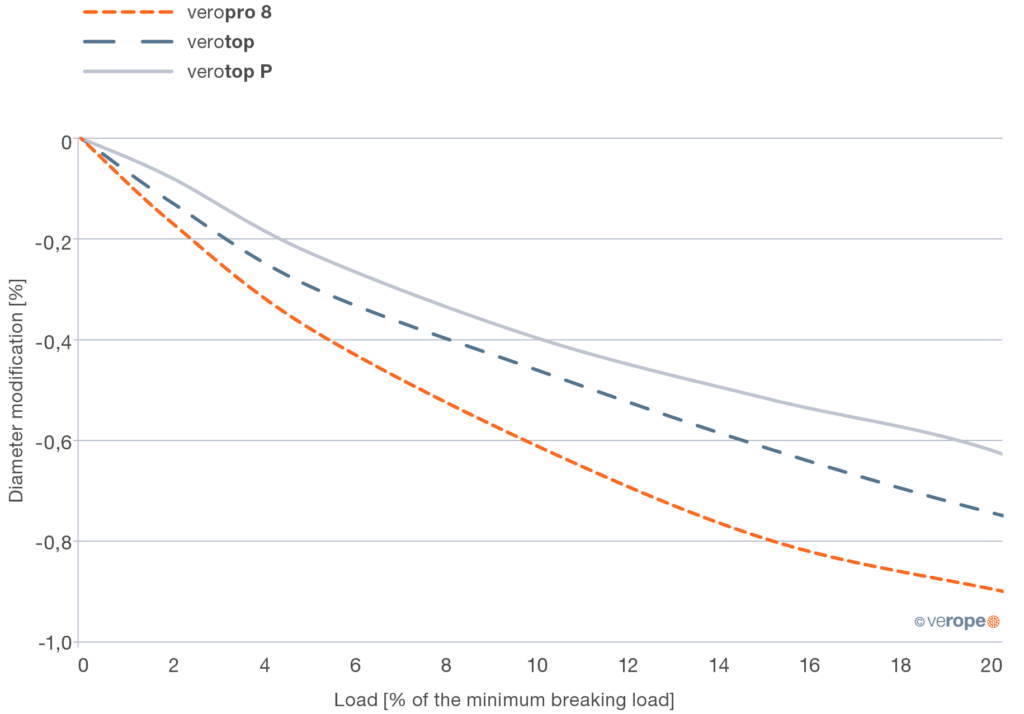

Diameter reduction

A rope becomes longer and thinner under load. The diameter reduction can influence the rope behavior in multi-layer spooling strongly. verope® has measured the diameter reduction of all its products and is pleased to provide you with the measured values if required.

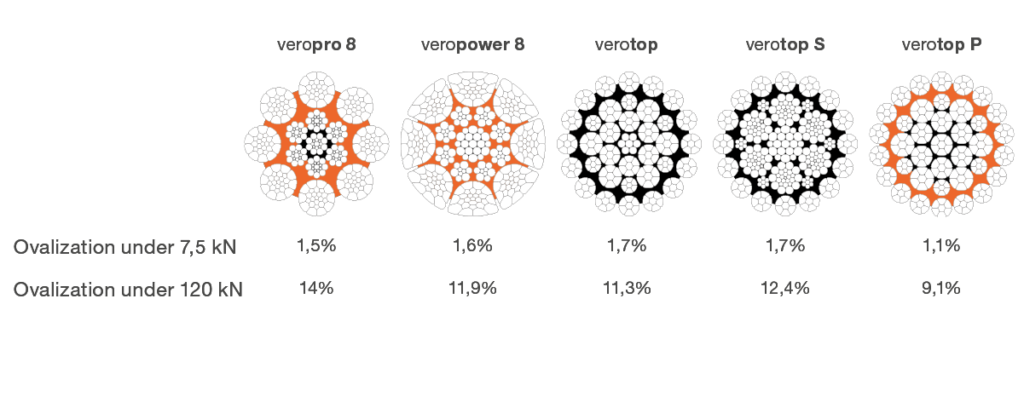

Lateral stability with and without load

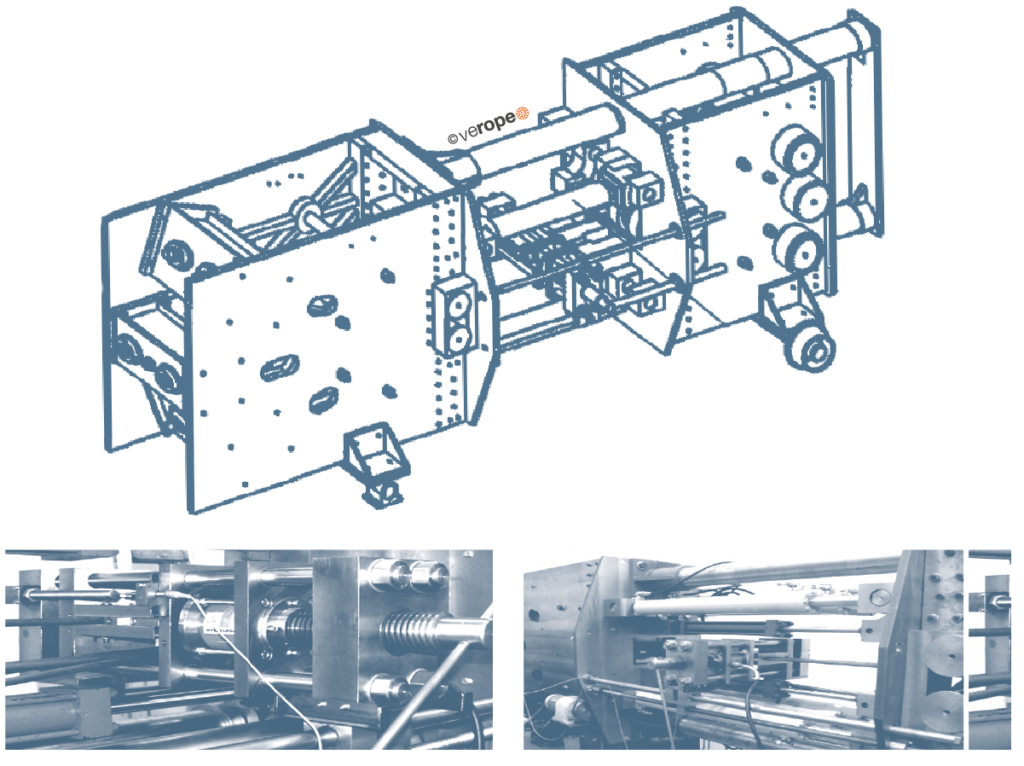

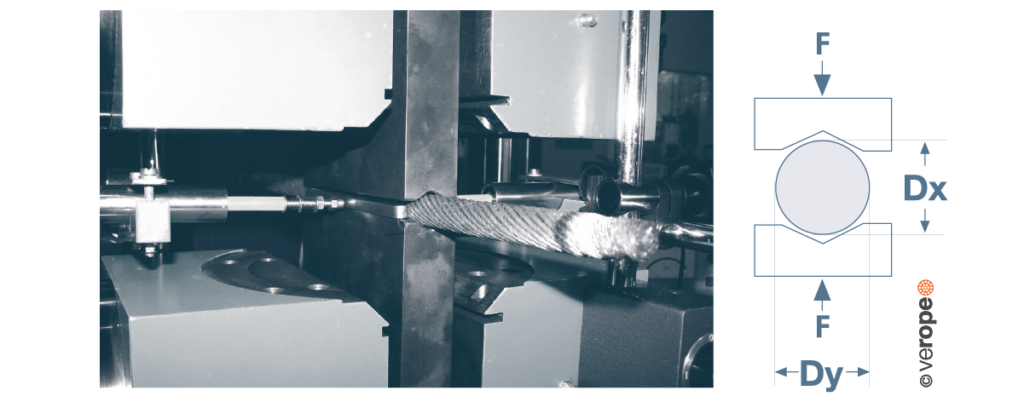

In multi-layer spooling, wire ropes are not only exposed to tensile and bending loads, but also to enormous transverse loads. In order to be able to withstand these loads and to avoid spooling problems, a high degree of radial stability is necessary. The radial stability of the rope also influences the deformation behavior of the drum. That’s why it is important for the designer of the drum to know the radial stability in the form of the transverse modulus of elasticity of the ropes. Radial stability is defined as the resistance of a wire rope against transverse (radial) deformation (Ovalization). verope® measures the radial stability of its products with (figure 62) and without load (figure 60 & 61).

Measurement under load

At the determination of the lateral modulus of elasticity under load, the deformation behavior of the rope is measured under various tensile loads and different transverse loads (figure 62). verope® has determined the lateral modulus of elasticity for all its products and is pleased to provide them to designers when required.