From the technical point of view there are two main categories, crane ropes can be divided into, when focusing on the rope application in cranes:

- rotation-resistant ropes – Sometimes colloquially also named as non-rotating ropes or multi-strand ropes

- Non-rotation resistant ropes

“Hoist Application”

As a basic guidance the following rule has proved one´s worth: For all “Hoist applications”, either main or auxiliary hoists, rotation-resistant Ropes are used exclusively, when:

- the load is unguided (figure 75) and/or

- high lifting heights are required

Only rotation-resistant ropes provide load stability so the load has no or little tendency to rotate. Rotation-resistant ropes that are fixed to the crane construction transmit no or little torque to the attachment point. Therefore rotation-resistant verope special wire ropes guarantee safe operation. Ropes that are defined as rotation-resistant according to the specified standards vary regarding their resistance to rotation depending on the construction type.

To show the difference regarding resistance to rotation different “classes” are formed.. For example EN 12385-4 nominates the rope class “35×7”, which describes rotation-resistant ropes having three layers of strands and the rope class “18×7” which describes rotation-resistant ropes having only two layers of strands. The rotation resistance of both classes, as well as the production cost clearly differ and herewith the prices will also vary .

In addition, as a further example, the ASTM A 1023 describes three rope categories, categorized by their resistance to rotation. Please find the two categories “1” and “2” that are widely used as hoist ropes in cranes:

- Category 1-rotation-resistant ropes have at least 15 outer strands and provide best resistance to rotation

- Category 2-rotation-resistant ropes have 10 or more outer strands

As general guidance rotation-resistant ropes considered being “35×7”-class ropes provide comparable resistance to rotation as category 1-ropes according to ASTM A1023 whereas rotation-resistant ropes considered being “18×7”-class ropes provide comparable resistance to rotation as category 2-ropes according to ASTM A1023. For demanding applications category1-rotation-resistant ropes have to be used.

Please Note: Ropes of the class “35×7″/category1 have to be replaced always by ropes of the same/comparable class and never by ropes of class “18×7″/category2. Whereas ropes of the class “18×7″/category2 can be replaced also by ropes of category1/”35×7” from a technical point of view.

Information: In addition to rotation-resistant ropes, which are manufactured according to national or international standards, there are many rotation-resistant ropes designed and manufactured “besides” the standard to meet even higher demands. These are real Special Wire Ropes, developed for highest demands regarding rotation resistance, for example highest lifting heights of modern cranes. To give customers general guidance about such special ropes the above mentioned standards are used as a reference to classify special ropes because the fundamental properties are comparable, although the performance is better.

Important: When rotation-resistant ropes are required, they must never be replaced by non-rotation-resistant ropes.

Usage of a swivel on hoist ropes

The usage of a swivel can be helpful to eliminate twist generated under certain circumstances within the rope drive, e.g. if fleet angles between the drum and the first sheave or between the sheaves are in some configurations above recommended limits. In multi-reeving applications the swivel can’t compensate twist in all falls but the first falls from the swivel. The swivel reduces the risk of either hook cabling or rope damages like waviness or basket deformation that can lead to rope discard.

Please note that ropes considered being “35×7”-class ropes/category 1-ropes according to ASTM A1023 could be used with or without a swivel.

EN 12385-3 and ISO 21669 give further information regarding the swivel usage.

verope’s® product range of rotation-resistant ropes

verope’s product range of rotation-resistant ropes contains the high-performance products that are part of the “-top”-series:

- verotop P

- verotop XP

- verotop

- verotop S

- verotop E

- and the 4-strand rope construction

- vero 4

With the exception of the 4-strand rope vero4 all our ropes are high performance category-1 rotation-resistant ropes, providing best resistance to rotation. All “top”-series crane ropes can be used either with or without a swivel.

The vero4-product, a very robust rope, is designed for harshest working conditions with dynamic impact loads. Although the vero4 rope is part of the rotation-resistant group the vero4-product may not be used with a swivel.

The basic rule for “Hoist application” is to use rotation-resistant ropes.

Following that rule you can’t fail but as with all rules there are exceptions under certain circumstances:

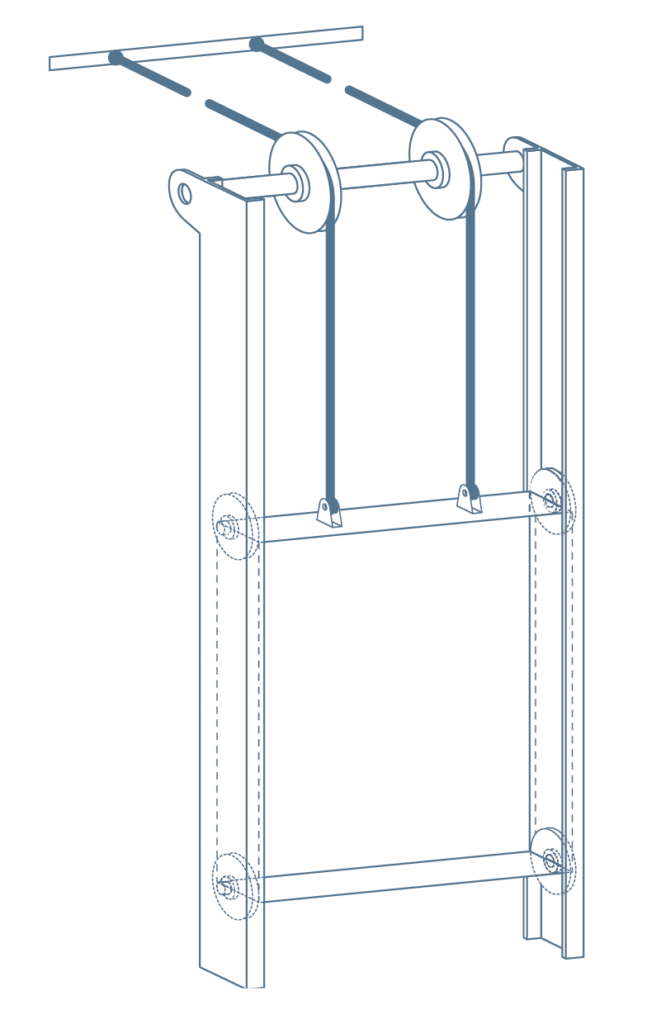

1. For “Hoist application” and guided loads non-rotation resistant ropes can be used too because the torque generated under load is held by the frame, guiding the load (figure 76).

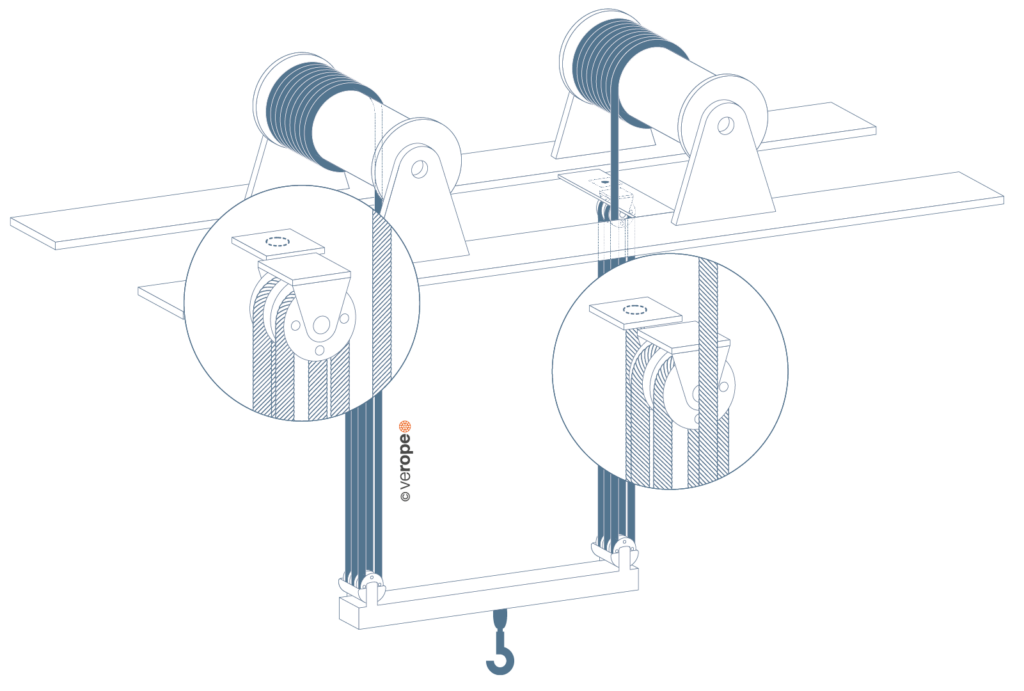

2. For “Hoist application” and unguided loads non-rotation resistant ropes can be used too, when the same rope construction ropes are used as a pair that consists of right and left hand ropes (figure 77).

The second configuration also provides rotational stability so the load has no or little tendency to rotate because the amount of torque generated under load is equal but in opposite directions: the result – torque equilibrium.

Important: Rotation-resistant ropes are clearly inferior regarding the bending cycle performance in comparison to non-rotation-resistant ropes. Therefore non-rotation-resistant ropes should only be replaced by rotation-resistant ropes under utmost care and after consulting with rope experts.

More crane applications

Non-rotation resistant ropes usually achieve more bending cycles than rotation-resistant ropes or semi-rotation resistant ropes. However, they exert a torque on the end fitting when under load.

Therefore non-rotation resistant ropes can only be used, if the ends of the ropes are permanently protected against twisting.

Non-rotation resistant ropes are always the right choice, when the characteristic “rotation-resistance”, which only rotation-resistant ropes offer, is not required. This is the case for many rope applications, e.g. for luffing ropes, trolley ropes, pendant ropes or installation.

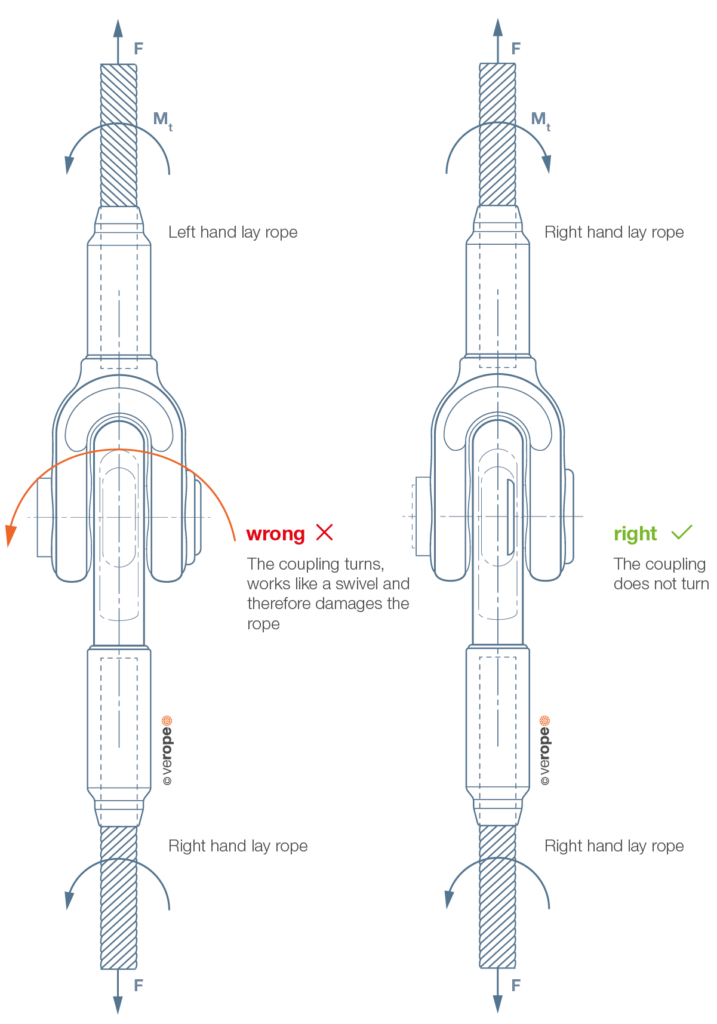

Note: With coupling of non-rotation resistant ropes, e.g. pendant ropes or grab ropes, only identical ropes of the same construction, meaning: the same diameter, the same lay type and lay direction have to be used (figure 78).

Combining ropes with different lay directions would turn up the ropes and thus destroy them.